We are celebrating the success of our Virtual Reality (VR) paint technology, having recorded notable sales and gained widespread international interest in the first 12 months since its launch.

Some 26 units are now being deployed across AkzoNobel and customer sites, more than half (15) of which are owned and operated by AkzoNobel Aerospace Coatings’ customers, with early adopters already realizing significant advantages.

Paris 2025

Our customers include OEMs, MROs, and industry education and training establishments, among them Embraer, International Aerospace Coatings (IAC), and The Machinists Institute. The units are proving popular across all geographies, with the technology operating in the Americas, EMEA, and APAC – clear evidence of an industry-wide and worldwide appetite for solutions that support a more sustainable aviation future.

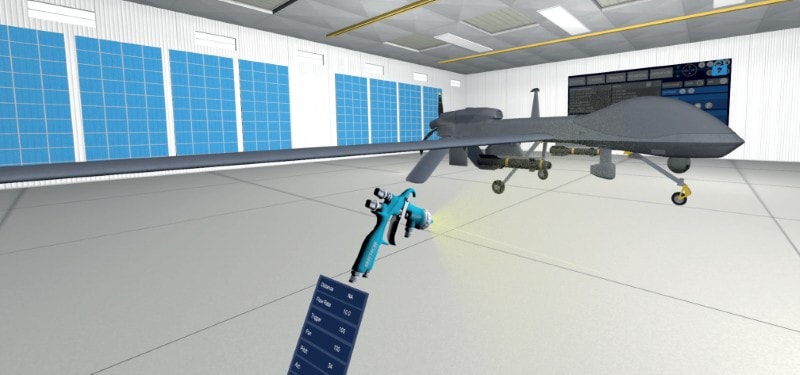

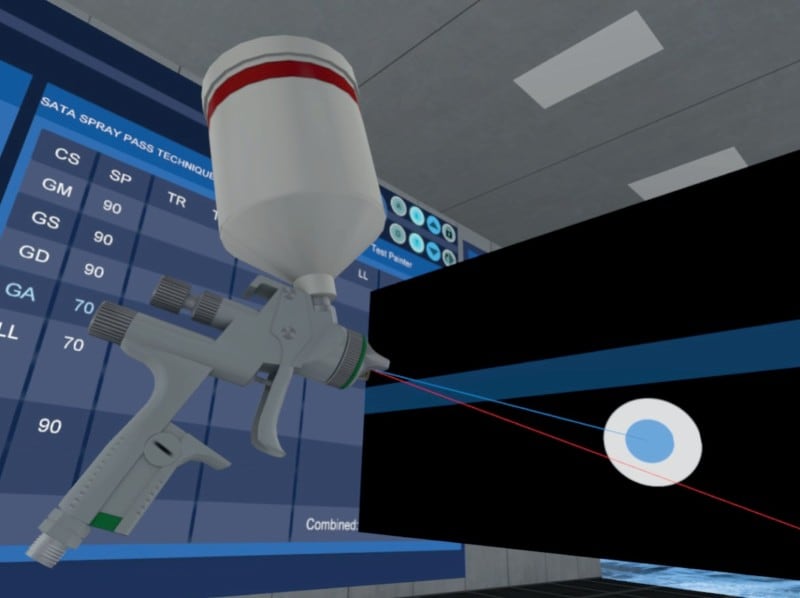

We first adopted VR technology in 2021 to deliver advanced training and technical service support. Initial early successes led to the launch of a dedicated VR training initiative in early 2024 as part of our wider Aerofleet Training+ portfolio. Our VR Training software immerses the individual painter in a virtual paint booth, complete with the aircraft part to be coated. It can be programmed with various paint parameters, such as coating thickness, overcoat times, and tailored spray gun setup.

Virtual paint booth, complete with the aircraft part.

As the operator uses the spray gun, they can see whether too much or too little paint is used and look for inconsistencies in the application. Their skills can be measured, including the distance, angle, and speed at which the gun is used. The system shows where runs and sags occur, where the wet film thickness is insufficient, or where the coverage is inadequate to deliver the desired finish.

While the system plays a critical role in training new painters or upskilling current professionals, it also delivers significant corporate advantages to early adopters by helping eliminate waste, reduce costs, and improve safety—since no physical products are involved. There are also no costs or time associated with cleaning spray guns, the additional VOCs from required solvents, or the panels needed for wet paint training.

Michael Green, Global Business Services Manager

Michael Green, Global Business Services Manager at AkzoNobel Aerospace, says that with VR, customers can train more painters, more efficiently, at a time that is convenient to them:

“With VR as an integral part of our Aerofleet Training+ portfolio, we’re helping OEMs, MROs and educational establishments to become significantly more efficient and sustainable,” he says.

“It is encouraging to see our first customers now taking multiple units, and to see how the concept is finding favour in all four corners of the globe. It’s an excellent example of a true partnership at work and demonstrates our commitment to enhancing sustainability in practical and meaningful ways.”

The introduction of our new VR concept is already delivering tangible results. IAC, which was the first MRO to acquire the technology and is now deploying VR worldwide, says that up to 70% of all new apprentice training can now be completed in the classroom—without a single drop of paint being sprayed.

IAC - First MRO to acquire the technology

The mobile nature of our VR technology enables International Aerospace Coatings (IAC) not only to train painters at its headquarters in Shannon but also at its other sites around the world.

John Mulqueen, VP Operations EMEA at IAC

John Mulqueen, VP Operations EMEA at International Aerospace Coatings, says the VR training has become integral to IAC’s global training:

“The system plays a huge role in the development and upskilling of our staff and personal growth within the company. AkzoNobel’s VR training mimics a real-life aircraft and projects so it allows the staff member to practice, train and upskill before moving onto a live aircraft. The system corelates exactly to an individual’s capabilities so it is a very efficient tool for skill development.”

“It’s an excellent motivational tool for our team,” John explains, “our staff enjoy using it and have some friendly competitions using the VR system. It’s brilliant for us as a company with developing and growing of our staff skill base. It is a real positive for our business which has given us greater flexibility of skillset within the teams.”